5 Gallon Water Bottling Plant

Different Water Bottling Production For choice

- NEP-200BPH Line, 200Bottle Per Hour

- NEP-300BPH Line, 300Bottle Per Hour

- NEP-450BPH Line, 450Bottle Per Hour

- NEP-600BPH Line, 600Bottle Per Hour

- NEP-900BPH Line, 900Bottle Per Hour

Benefits:

- Tailored for 3, 5, and 6-gallon bottles.

- Efficiently addresses challenges related to reused bottles.

- Thorough washing and quality checks ensure cleanliness.

- PLC control ensures precision in the filling process.

- Pressure capping system ensures secure sealing.

- Shrink tunnel enhances the presentation of the final product.

Neptune Machinery Company proudly presents its fully automatic 3 to 5-gallon water bottling plant, designed for the efficient production of bottled water in various sizes, including 3-gallon, 5-gallon, and 6-gallon bottles. This comprehensive bottling line is specifically tailored to address the unique challenges of the 5-gallon bottle water business, emphasizing the reuse of bottles that often have caps on the mouth and may not be clean.

Key Features:

- Bottle Placement:

- Workers place empty bottles on the conveyor belt, initiating the bottling process.

- Cap Removal:

- The cap removal machine efficiently removes caps from the bottles.

- Caps are inspected to ensure quality.

- Brusher Washing:

- Bottles undergo thorough inside and outside washing using a specialized brusher washing machine.

- Loader Machine:

- The loader machine turns the empty bottles 180 degrees, preparing them for the next stages.

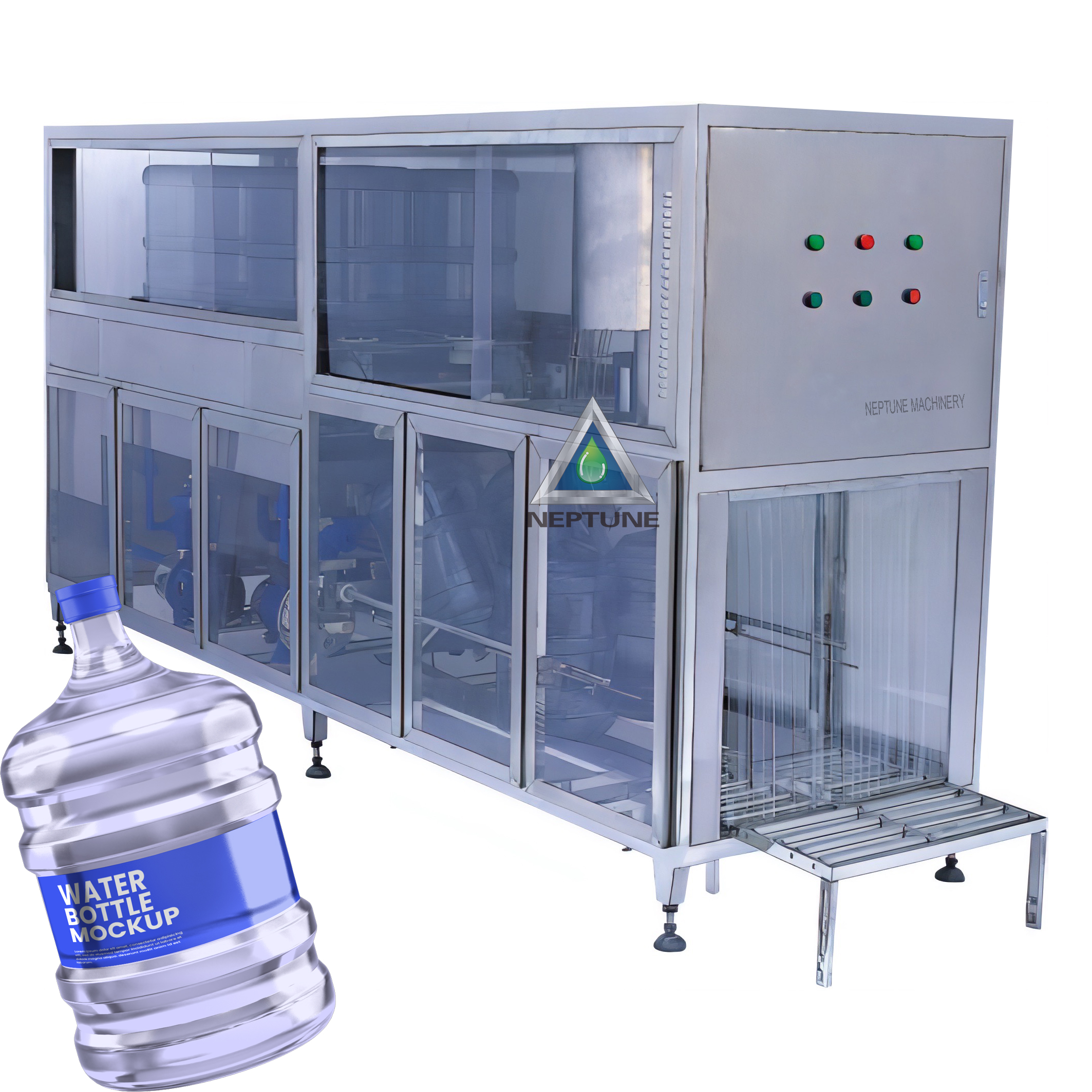

- Filling Machine:

- The filling machine incorporates a 4-station washing system for optimal cleanliness.

- Stations include NAOH food-grade medicine washing, hot washing, city water washing, and pure water washing.

- Pure Water Filling:

- PLC-controlled filling ensures precise and sufficient filling of pure water into each bottle.

- Capping:

- Bottles are capped using a pressure capping system, ensuring secure sealing.

- Shrink Tunnel:

- Bottles, now with mouth labels, pass through a shrink tunnel for a secure and visually appealing seal.

Neptune Machinery Company’s automatic 3 to 5-gallon water bottling plant is a reliable and advanced solution for businesses in the bottled water industry, providing efficiency and quality throughout the entire production process.

Video of the 5 Gallon Water Bottling Plant

| Product volume | 3gallon to 6gallon |

| Speed of production | 200 bottles/hour to 900 bottles/hour |

| Budget | $14000 to $55000 |

| Filling Product | Pure water, spring water, mineral water |

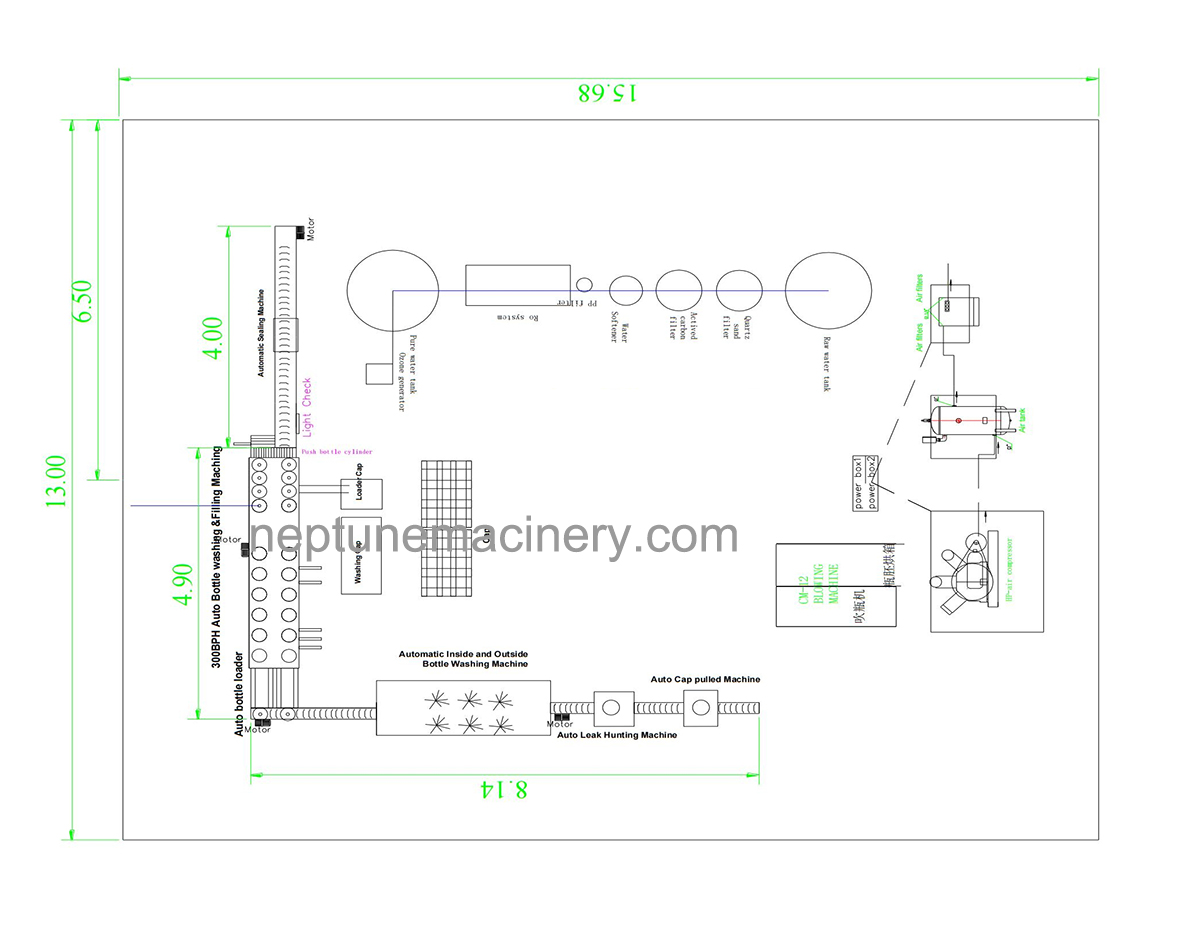

Reuse bottle, 5 Step Washing

1. Brusher Outside Washing 2. Brusher Intside Washing

Like the removed cap, check bottle leak, and brusher washing, water push washing. 60% of this bottling line is to make sure the reuse bottle treatment into clean and safe.

5Gallon bottle is rerecycle use. Every time got back from customer need a lot treatment to make sure it clean and safe.

3. NaOH push washing 4. City water washing 5. Pure washing push washing.

Working Process of the water bottling plant

Key Points:

- The process is designed to handle the challenges associated with reused bottles.

- Thorough washing at multiple stages ensures cleanliness and quality.

- PLC control in the filling machine ensures precision in water filling.

- Pressure capping system guarantees a secure seal.

- The shrink tunnel enhances the presentation of the final product.

Description of the Automatic 3 to 5 Gallon Water Bottling Plant Process:

- Bottle Placement:Workers place empty bottles onto the conveyor belt to initiate the bottling process.

- Cap Removal:The conveyor belt moves bottles to the cap removal machine.

- Brusher Washing: Bottles move to the brusher washing machine.

- Loader Machine:The loader machine turns the empty bottles 180 degrees, preparing them for the next stages.

- Filling Machine with Washing:

- Bottles move to the filling machine, which includes a washing part.

- Water push washing is employed, with four stations for optimal cleanliness:

- 1st Station: NAOH food-grade medicine washing

- 2nd Station: Hot washing

- 3rd Station: City water washing

- 4th Station: Pure water washing

- Pure Water Filling:PLC control ensures precise and sufficient filling of pure water into each bottle.

- Capping:Bottles are capped using a pressure capping system, ensuring a secure seal.

- Shrink Tunnel:Bottles, now with mouth labels, pass through a shrink tunnel for a secure and visually appealing seal.Workers sleeve mouth labels onto the bottle mouths prior to this stage.

- Caps are removed, and a quality check is performed to ensure proper cap removal.

- Brushes are inserted into the bottles for thorough washing of both the inside and outside.

Neptune Machinery Company’s automatic 3 to 5-gallon water bottling plant is equipped with advanced features to meet the specific requirements of the 5-gallon bottle water business, offering efficiency and high-quality output.

Automatic 5 Gallon water filling line save labor

Whole line only need 3workers, one putting empty bottle , one looking after by side, one final carry the bottle water to storage room

All parts contacting water are made of 304L stainless steel, with ozone-resistance and in compliance with food-grade standards. Nozzles are inserted to rinse the bottles thoroughly.Fast cycle system is adopted for heated alkali rinsing, drastically decreasing electricity consumption.Controlled by PLC, it is fully automatic.

All line controlled by PLC, the water bottling machine integrates the functions of 3/5 gallon bottle washing, filling and capping on one set of machine.

It is manufactured in compliance with the standard of American Drinking Water Industry Association, and with reference to overseas newest type of machine

It not only have advanced technology, high automatically, easy operation and reliable performance, but also small size, small weight and beautiful appearance, anti-corrodibility, thorough disinfection, effective antipollution and high quality. The device employs key components of electrical appliances and metal materials manufactured by brand factories at China and abroad. Nonmetallic components are manufactured elaborately by wearable materials, such as nontoxic PP plastic, etc.

Small Invest, Big Profit

5 Gallon bottled water business is the most mature water business.

Usually factory directly sell to water shop station or family. The production is not as high as small bottle water plant. For example, The most popular line is just 300bottles per hour. One day 8hour running, it is 2400bottles per day. It is enough for a city of 50,000 peoples.

One 5gallon or 19l 20l bottle water sell at 0.71dollar.

The water materials cost very less. And the bottle is reuse. The mostly cost is the porter who handing the bottle water to customer family.

If factory just profit 0.3dollar per bottle. So one day can profit 2400*0.3=720dollar.

Per year 365*720=26280dollar. When an plant cost 1/10 of the profit.