It is an market demand orientation machine. 7years before. The smallest monoblock water bottling machine is 16-12-6 type which capacity of production is 4000bottles per hour.

But a lot bottle water company demand only 2000 bottles per hour bottling machine. At that time, most customer just can buy 16-12-6 water bottling machine to setting smaller capacity of production. It is waste extra cost for no use capacity. That still happen in a lot company.

According to this market demand. NEPTUNE MACHINERY design the 883 water bottling machine. Its capacity of production is 2200-2800 bottles per hour.

8-8-3 Monoblock water bottling machine

It is the latest rotary type 3-in-1 water bottling machine. It is the cheapest type 3-in-1 monoblock filling machine in the world.

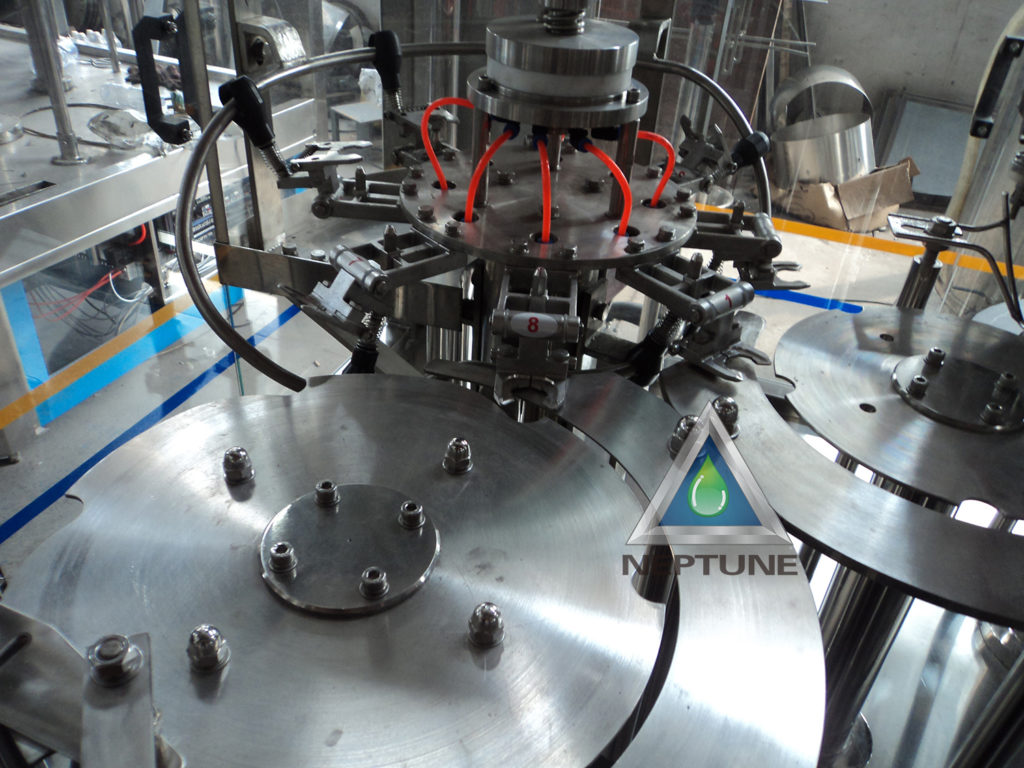

It collects washing, filling and capping together monoblock. It is driven by a transmission motor. It is mainly suitable for rotary bottling round plastic bottle or square polyester bottles.

According to the demand of different specifications of users. It can through change shape mold to production different volume and shape bottled water.

Advantages of the water filling machine 883

- PLC control

- High automation level

- Compact structure,

- Beautiful appearance

- Convenient and simple operation

- Safe and reliable

- Adjustable continuous production capacity

- 8 sets of catch bottles and manipulators for washing bottle. The bottles are equipped with rotary seal inside and outside flushing and water return mechanism.

- 8 sets of filling valves

- Arrange bottle caps equipment

- 3 sets of magnetic twist full-tooth capping heads. When the torque exceeds the adjusted magnetic force, the capping heads will automatically slip to ensure that the caps will not be damaged by tightening them.

- 4 sets of safety devices for removing bottles. No bottles will be filled or capped.

- The host adopts advanced frequency control technology.

Monobloc bottle water filling working process

Bottles are fed from conveyor chain into the filling machine monoblock via star wheel. Bottle clamp installed on the rotary wheel of the rinse will grip bottle mouth and make a 180° turn along a guide track to face the bottle mouth downward.

In designated section of the rinse, rinsing water will jet out from special nozzles to flush bottle inside wall. After rinsing and dripping, bottles gripped by bottle clamp will make another 180° turn along a guide track to resume bottle mouth facing up position.

Clean bottles are discharged out of the rinse by a star wheel to feed the filler. After entering the filler, bottles are retained by neck supporting carrier plates, which are actuated by bottle carrier mechanism to raise them to engage with filling valves. Filling valves are opened by bottle presence signals.

After finishing filling, valves are closed by valve closing mechanism to further stop venting to complete the filling process. Bottle carrier mechanism is lowered by a cam to disengage filled bottles with filling valves. Then bottles are transferred into the capper by a neck handling star wheel.

Anti-rotation blades on capping heads will seize the bottleneck to prevent it from rotation and hold it in a upright position. The twist-on capping head will make revolving and rotating movement along with the machine to finish the complete capping process of cap picking, placing, twisting, and disengaging under the control of a cam. A discharge star wheel discharges finished bottles onto discharge conveyor belt to be conveyed out of the filling monoblock.

It is the key filling machine of the complete nep-s2500 water botttling plant .

The Video of the 8-8-3 bottled water filling machine

| NO | NAME | QC | BRAND |

| 1 | Main motor | 1SET | Suzhou |

| 2 | Sorting machine | 1SET | Zhongtai |

| 3 | Jet pump | 1SET | NT pump |

| 4 | Liquid inlet pump | 1SET | NT pump |

| 5 | Conveying motor | 1SET | Taizhou |

| 6 | Air blower | 1SET | Wuxi |

| 7 | PLC | 1SET | MITSUBISHI |

| 8 | Frequency converter | 1SET | Xilin |

| 9 | Circuit breaker | 1SET | Delixi |

| 10 | Circuit breaker | 1SET | Delixi |

| 11 | AC contactor | 5SET | Delixi |

| 12 | Thermal relay | 5SET | Delixi |

| 13 | Touch screen | 1SET | Xinje |

| 14 | Communication cables | 1SET | Xinje |

| 15 | Approach switch | 1SET | Korea |

| 16 | Cap photoelectric measurement | 2SET | Korea |

| 17 | Connection terminal | 1SET | Shanghai |

| 18 | Emergency stop button | 1SET | Shanghai |

| 19 | Power indicator | 1SET | Shanghai |

| 20 | A burglar alarm | 1SET | Shanghai |

| 21 | Speed potentiometer | 1SET | Shanghai |

| 22 | Send cap | 1SET | Shanghai |

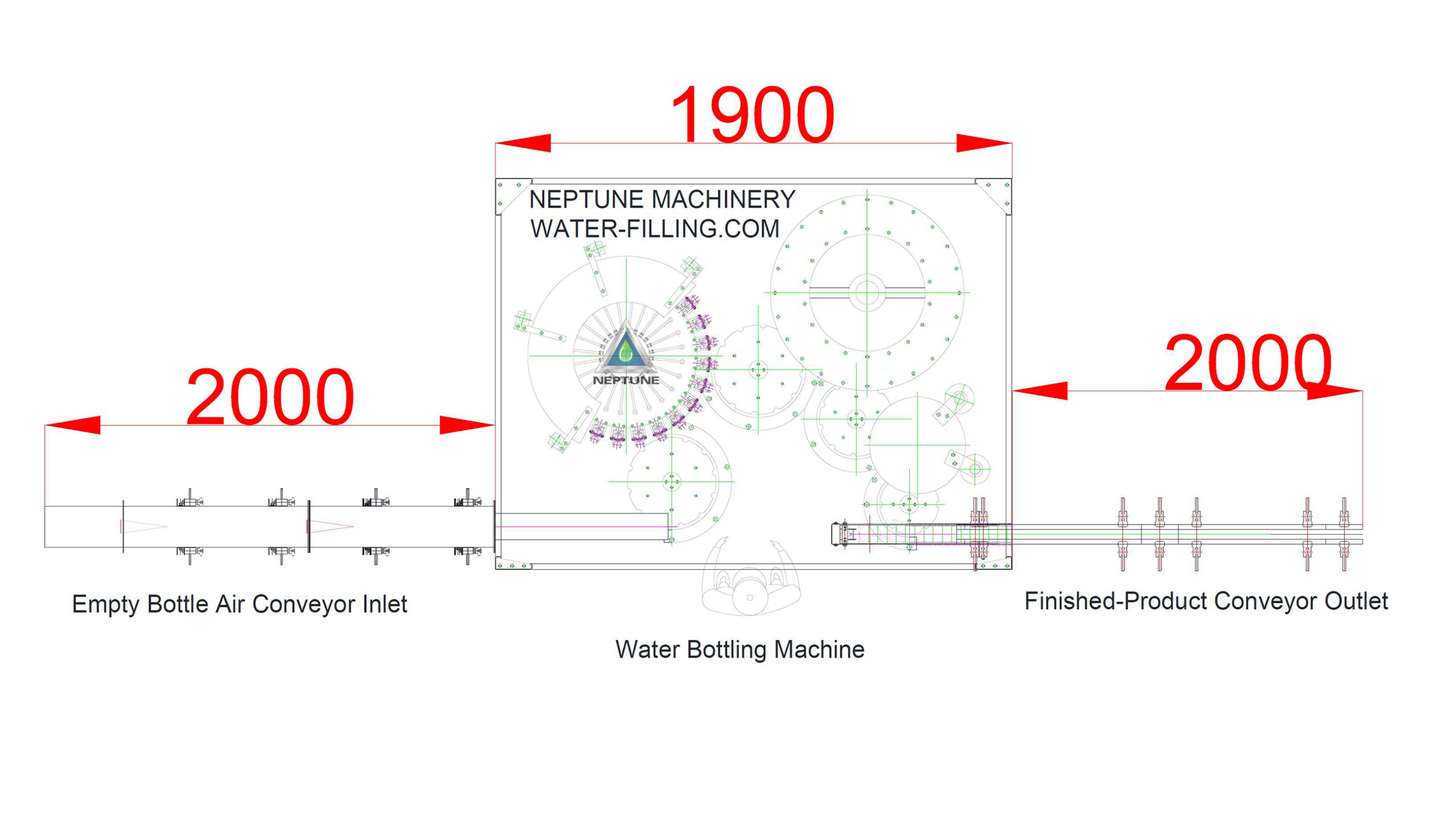

Layout of the 883 water bottling machine

883 water bottling machine inlet empty bottle is air conveyor way. It is the two conveyor steel just catch and hold the empty bottle neck. Then made use of the air fan blowing air to conveyor the empty plastic bottle. NEPTUNE 883 water bottling machine come with 2 meter air conveyor and 1 set fan.

The finished capper well bottled water is almost an half finished product. It is transfer to the next machine by conveyor belt. Conveyor belt driven by motor. NEPTUNE 883 water filling machine with 2 meter conveyor belt and 1 set motor.

FAQ

Dilivery time ?

Produce 20days, then is shipment time depend on ship.

Does the machine cheap meanning low quality ?

In past, neptune smallest 3-in-1 filling machine is 16-12-6 type which capacity is 4000 bottles per hour. And 8-8-3 bottled water filling machine is an market demand reverse design type. It is inquiry by an lot customer who just need 2000 bottles per hour capacity. Then neptune design and produce it. Its save a lot spare part and materials. So its price is cheap.

What this filling machine capacity ?

2000 Bottles per hour depend on 500ml bottled water.

1500 Bottles per hour depend on 1000ml bottled water.

1200bottles per hour depend on 1500ml bottled water

Do neptune company offer oversea installation ?

Yes. We offer engineer aboard installation.

Because recent 3 years covid -19 limit, we only can send Africa branch maneger engineer fly to different Country installation. NEPTUNE 100% make sure install well the machine and running well over 10years.