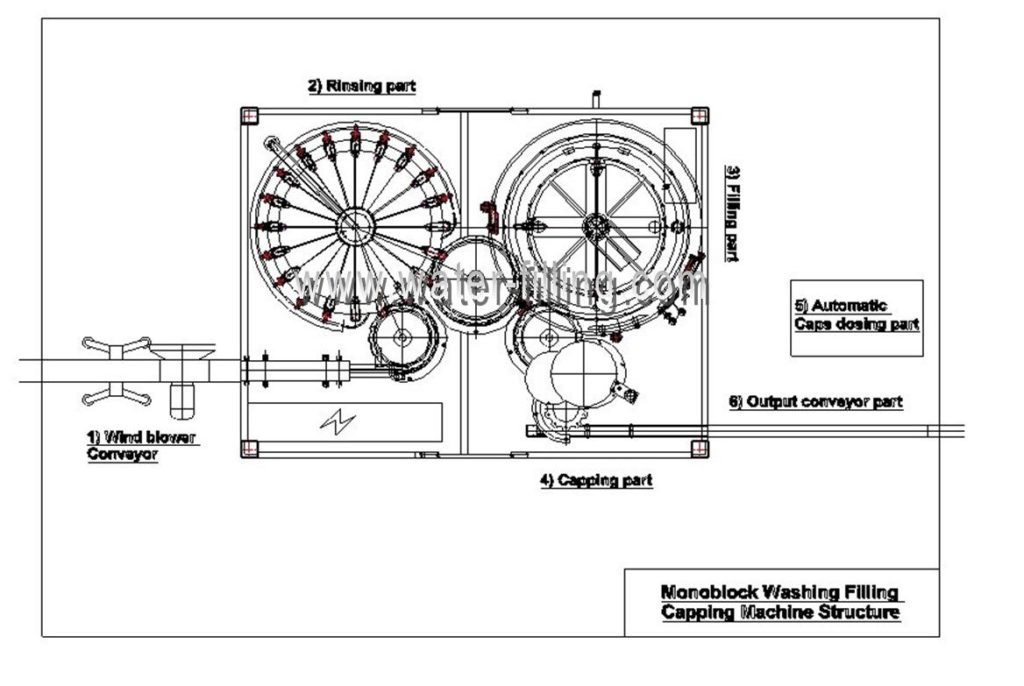

Water bottling machine three in one collects washing, filling and capping in one unit. It is driven by a transmission motor.

Advantages of high automation level, compact structure, beauty appearance, convenient operation, safe and reliable, adjustable continuous production capacity.

It is an ideal beverage filling production equipment. Mainly suitable for washing, filling and capping round or square polyester bottles.

Drink Kind: Mineral Water, Pure Water, Fruit Juice, Wine and other no-gas liquid.

Main Technological Parameters

| Production Capacity | 6000-7000 bottles/h |

| Washing Head Quantity | 18 |

| Filling Valve Quantity | 18 |

| Capping Head Quantity | 6 |

| Filling Temperature | Normal temperature |

| Filling Type | Constant Pressure Filling |

| Main Motor Power | 3KW |

| Ordering-Cap Motor Power | 0.09KW |

| Cap Elevating Motor Power | 0.34KW |

| Washing Pump Power | 0.37KW |

| Liquid Inlet Pump Power | 0.55KW |

| Air Convey Motor | 1.1KW |

| Reflux Pump | 0.37KW |

| Consume Water | 1.2T/h ( Un-including drink water) |

| Control Type | PLC |

| Central Diameter of Filling Valve | ¢720mm |

| Central Diameter of Capping Machine | ¢240mm |

| Central Diameter of Washing Machine | ¢720mm |

| Dimension | 2520 X 1970X2300mm |

| Net Weight: | 2500kg |