3-IN-1 Water Bottling Machine is a comprehensive solution that combines the processes of washing, filling, and capping into a single integrated system. Here’s an introduction to its features:

- Functionality:

- The machine is designed for the washing, filling, and capping of round or square polyester (PET) bottles.

- It is suitable for various bottle sizes, ranging from 200ml to 2000ml, and can be adapted to different shapes.

- Technological Basis:

- Developed based on German filling machine technology, the 3-IN-1 Filling Machine reflects advancements in the field.

- NEPTUNE has continuously updated and refined the technology for over 20 years.

- Drive System:

- The machine is powered by a transmission motor, providing efficient and reliable operation.

- Advantages:

- High Automation: The machine boasts a high level of automation, reducing the need for manual intervention.

- Compact Structure: The design features a compact structure that optimizes space utilization.

- Beautiful Appearance: The machine is aesthetically pleasing, contributing to a modern and attractive production environment.

- Convenient Operation: Operation is designed to be convenient and simple, facilitating user-friendly control.

- Safe and Reliable: The machine prioritizes safety and reliability in its design and functionality.

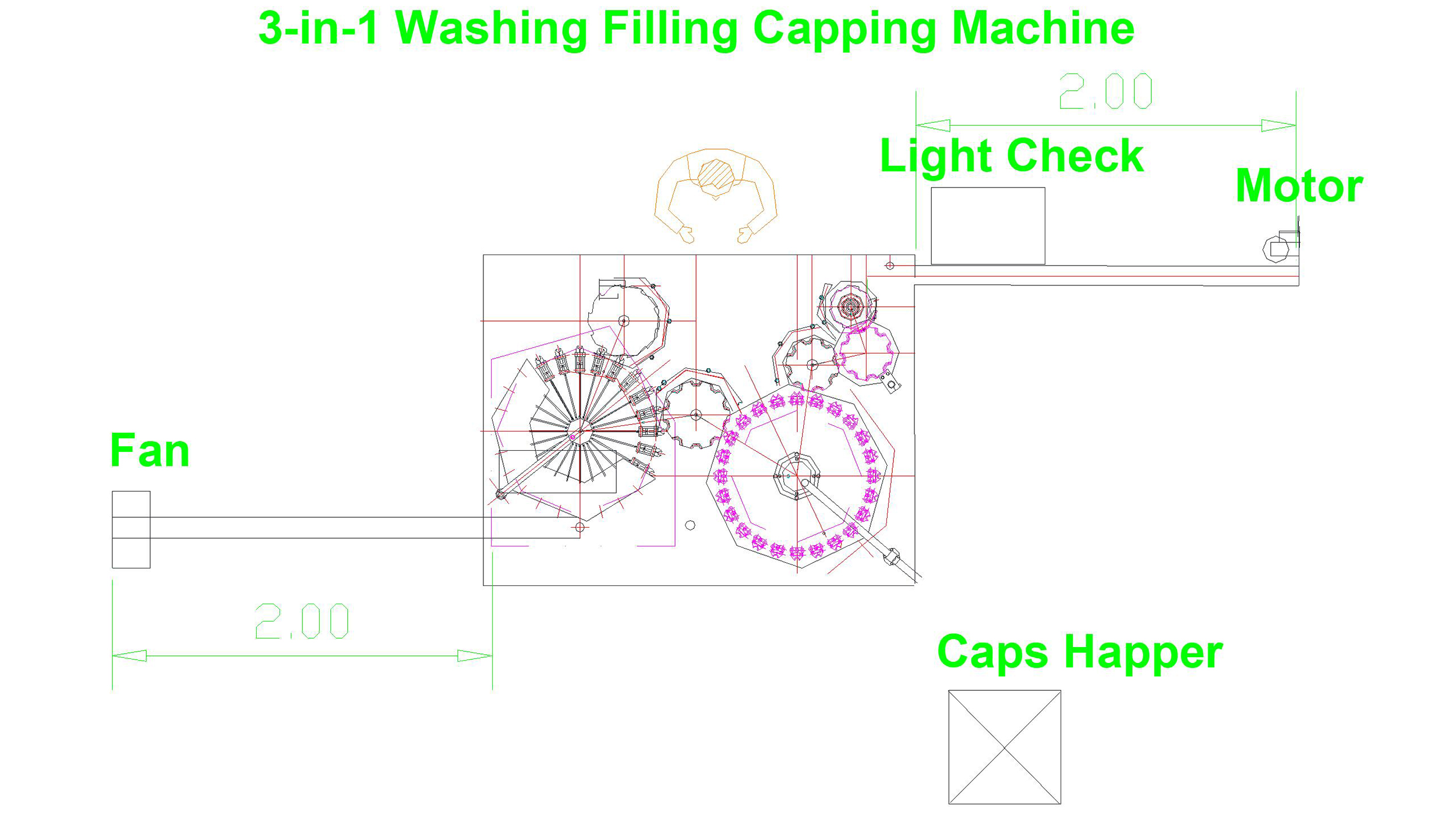

- Components:

- Air Conveyor: Transports bottles through the various stages of the bottling process.

- Rinser-Filler-Capper Monobloc: Integrates the three key functions of washing, filling, and capping.

- Cap Lifter: Facilitates the lifting and application of caps onto bottles.

- Light Checking Box: Ensures the quality of the filled and capped bottles through visual inspection.

The 3-IN-1 Water Bottling Machine offers a comprehensive solution for efficient and streamlined bottling processes, making it a valuable asset in the beverage production industry.

Technological Parameters

Filling Temperature: Normal temperature

Filling Type: Constant Pressure Filling

Main Motor Power: 2.2KW

Ordering-Cap Motor Power: 0.09KW

Cap Elevating Motor Power: 0.34KW

Washing Pump Power: 0.37KW

Liquid Inlet Pump Power: 0.55KW

Consume Water: 1.2T/h ( Un-including drink water)

Control Type: PLC

Central Diameter of Filling Valve: ¢480mm

Central Diameter of Capping Machine: ¢240mm

Central Diameter of Washing Machine: ¢640mm

Dimension: 2100 X 1500X2200mm

Net Weight: 3500kg

Capacity Scale of Bottle: 350-2000ml;

Diameter Scale of Bottle: 50mm-90mm;

Height Scale of Bottle: 160mm-310mm;

Drink Kind: Mineral Water, Pure Water, Flavor water without sugar.

Main configuration:

1) Material of filling valve and liquid tank is 304

2) Main motor:National brand

3) Sliding bearing:Taiwan

4) Frequency inverter: MITSUBISHI

5) Touch screen:Taiwan

6) PLC:MITSUBISHI

7) Pneumatic components:Airtac

8) Seals:National brand

9) Photocell switch and proximity switch:Taiwan

Advantages

1. Bottle-necks clamping design: the bottle-necks are clamped and the bottles are suspended during the production process, such that guaranteed a stable filling process. And malfunctions can also be avoided for different bottle thickness and height.

2. Advanced isobaric filling technology form Germany and Italy helps making sure accurate control of liquid amount during filling process and quick filling.

3. No damage to bottle caps: the force for cap screwing could be adjusted freely for the adoption of magnetic torque. And there is also no damage to bottle caps.

4. Our special cap-managing device can avoid damaging to cap surface. And the function of auto-feeding for bottle caps is equipped.

5. Human-machine interface touch-screen is available in this liquid filling equipment: the liquid level in the tank can be controlled automatically. The filling and capping will stop automatically when there is no bottle.

6. Hygienic and safety: All parts that have direct contact with the beverage are made of high quality stainless steel. And the main electrical components are from famous international companies.

Three main part of the bottling machine

Rinser(16psc washing head)

- The rotary wheel is a fully AISI304 stainless steel welded structure.

- The high efficiency atomizing spray nozzle installed on bottle clamp incorporating technology from Spaying Systems Co. Ltd., is capable of cleaning any part of bottle inner wall, and also saves rinsing water.

- Covering of bottle clamps and elevator are product of IGUS

- The rinse is driven by driving system positioned inside machine frame via gear transmission.

Filler(12psc filling head)

- The filler is designed and manufactured with application of Italy technology, providing hardware guarantee for securing product quality and reducing loss.

- Rotary wheel are fully made of stainless steel AISI304.

- Filling valves are designed and manufactured with German technology, made of AISI316L, featuring high filling accuracy and high filling speed.

- Bottles are raised and lowered by cam controlled lifting cylinder. Valve opening mechanism is actuated by air cylinder.

- All sliding bushes of lifting device use Igus (Germany) anti-corrosion maintenance free bearing.

Capper(6psc capping head)

- The capper is most precise part in 3 in 1 filling machine, because the quality of machine is important to running credibility and product quality.

- The cover track has the device to prevent the reversal cover from passing and pick out the reversal cover. Meanwhile the photoelectric switch can stop the machine automatically when there is no cover on the track, by which it can avoid bottle without cover effectively.

- It also has the bottle check-up switch. Together with cylinder on the joint of the cover track and cover lift, they can control the cover flow and stop it in case no bottle to reduce the quantity of cover.

- Highly effective acentric way for cap sorting to reduce the abrasion.

- It has the check-up device to control the cover lift.

Video of the 3-in-1 filling machine

Advantages

1. Bottle-necks clamping design: the bottle-necks are clamped and the bottles are suspended during the production process, such that guaranteed a stable filling process. And malfunctions can also be avoided for different bottle thickness and height.

2. Advanced isobaric filling technology form Germany and Italy helps making sure accurate control of liquid amount during filling process and quick filling.

3. No damage to bottle caps: the force for cap screwing could be adjusted freely for the adoption of magnetic torque. And there is also no damage to bottle caps.

4. Our special cap-managing device can avoid damaging to cap surface. And the function of auto-feeding for bottle caps is equipped.

5. Human-machine interface touch-screen is available in this liquid filling equipment: the liquid level in the tank can be controlled automatically. The filling and capping will stop automatically when there is no bottle.

6. Hygienic and safety: All parts that have direct contact with the beverage are made of high quality stainless steel. And the main electrical components are from famous international companies.

Monoblock filling machine working process

The described process outlines the operation of a monoblock filling machine in a water bottling line. Here’s a summary:

- Bottle Feeding:

- Bottles are fed into the monoblock filling machine via a conveyor chain and star wheel.

- Rinsing:

- The bottle clamp on the rotary wheel grips the bottle mouth, making a 180° turn to face the bottle mouth downward.

- In the rinse section, rinsing water is jetted out to flush the bottle’s inside wall.

- Bottles make another 180° turn to resume the bottle mouth facing up position after rinsing and dripping.

- Transfer to Filler:

- Clean bottles are discharged from the rinse by a star wheel to feed into the filler.

- Bottles are retained by neck-supporting carrier plates, raised to engage with filling valves.

- Filling:

- Filling valves are opened by bottle presence signals.

- After filling, valves are closed to stop venting, completing the filling process.

- Transfer to Capper:

- Bottle carrier mechanism lowers, disengaging filled bottles from filling valves.

- Bottles are transferred into the capper by a neck handling star wheel.

- Capping:

- Anti-rotation blades on capping heads seize the bottle neck to prevent rotation.

- The twist-on capping head revolves and rotates, completing the capping process under cam control.

- Discharge:

- A discharge star wheel releases finished bottles onto a conveyor belt for further transportation out of the filling monoblock.

This process ensures a seamless and automated flow of rinsing, filling, and capping within the monoblock system, optimizing efficiency in water bottling operations.