Water Bottling Machine 2000BPH Linear Type

It is mainly included three bottling machine. The washing machine, the filling machine and the capping machine. Firstly, the washing machine is use to washing the plastic bottle with the push pure water. Secondly, the filling machine is use to filled pure water into plastic bottle. Thirdly, the capping machine is screw cap on the bottled water.

The whole bottling production process adopt stepless speed regulation having advanced structure. It is placidly and reliable. It is very easy to operate and low failure rate. Its cost is lowest in all water filling machine. And it is most like by first start bottled water business.

Trait of the inline water filling machine

Production capacity: 2000Bottles/hour,

Filling bottle specification: 250ml-1500ml.(Up1500ml bottle machine need customize,not need premium)

Filling bottle size: (unit: mm) Diameter:50-100 bottle height: 150-235mm

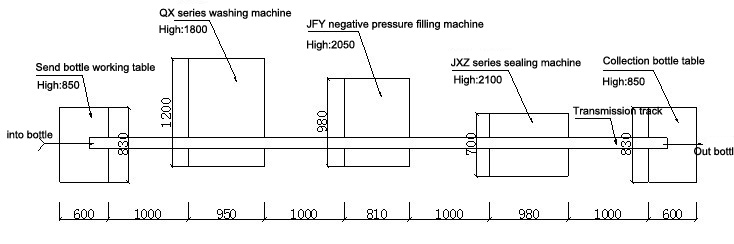

Layout of inline 12-12-1 water bottling machine

Equipment list of Linear Water Bottling Machine

- QS-12 Auto Bottle Washer

- CY-12 Normal Pressure Filler

- FXZ-1 Screw Capper

- 6 Meters Conveyor belt

- Motor.

- Loader Bottle Table

- Finished Product Tabel

1.QS-12 Auto Bottle Washer

It is one of the most versatile medium speed rinser available anywhere.It is designed to effectively internally rinse up to 3,000 small bottles per hour/50 bottles per minute.It’s ideal for rinsing bottles ranging in size from 12

oz (335ml) up to 2liters.The change over from one size bottle to another couldn’t be easier.It takes literally minutes and no tools are required nor are there any special molds or adapters required for the change overs.The stainless steel construction ensures years of a long and durable life for the system.and since there are a minimum of moving parts,maintenance to keep the system operating and maximum effciency is a snap

| 1 | Dimension(L×W×H) | 1200×1200×1800 mm |

| 2 | Weight | 960kg |

| 3 | Motor Power | 0.55KW |

| 4 | Production Capacity | 2000B/h (for 0.5L bottle) |

| 5 | Suitable bottle size | Diamater: Φ50~Φ100mm Height: 120~320mm |

| 6 |

2.CY-12 Normal Pressure Filler

CY-12 Normal Pressure Filler& 24 Foot automatic conveyor System: It is designed to automaticlly fill up to 3,000 bottles per hour and provides maximum versatility to keep pace with the demands of your operation.It is designed and built to operate multiple shifts with a minimum of the maintenance and does not requir highly skilled operators.The stae-of-the-art design and components offer maximum performance,reliability and versatility to fill from 335ml up to 2liter bottle.

| 1 | Dimension(L×W×H) | 1200×1000×1950 mm |

| 2 | Net Weigh | 750kg |

| 3 | Total Power | 0.92KW |

| 4 | Production Capacity | 2000B/h (for 0.5L bottle) |

| 5 | Suitable bottle size | Diameter:40~100mm Bottle height: 50~235mm |

| 6 | Filling Accuracy | Liquid level ±3mm |

3.FXZ-1 Screw Capper

FXZ-1 Screw Capper is also one of the most unique capping systems available.To begin with,the filled bottles first enter the build-in Bottles Spacing Mechanism.The bottles spacer allows for precise and constant bottle spacing while entering the Cap Applier.This correct spaceing ensures that your caps are applied evenly and consistently with the most accurate alignment possible.In preparation for cap appliation,caps are first moved,from the shipping carton,into the Cap Hopper.

| 1 | Dimension(L×W×H) | 920×740×1950 mm |

| 2 | Weight: 350kg | |

| 3 | Motor Power Cap Orderer Power | 0.55KW 0.12KW |

| 4 | Production Capacity(in theory) | 2400B/h (for 0.5L bottle) |

| 5 | Suitable bottle size | Diameter: Φ50~Φ100mm Height: 150~330mm Mouth Screw Diameter: Φ27.5 Theft Proof Cap Size: Φ28×15(inner size) |

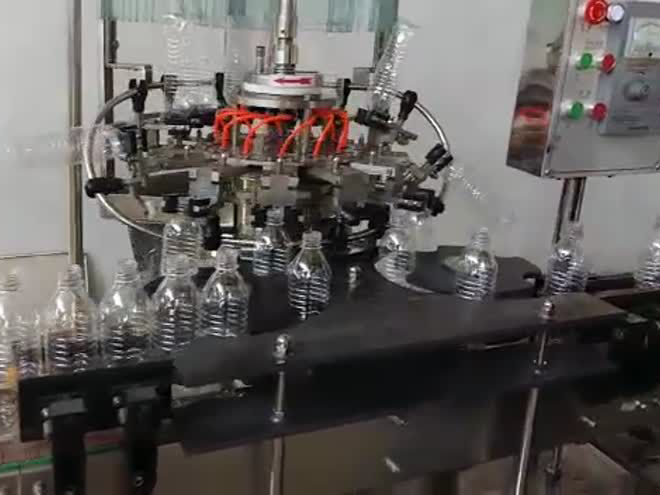

Video of inline water bottling machine

It is the bestselling water bottling machine.

Most bottled water company start bottled water business with this machine

It is continued running without waiting.

Know more about whole bottle water production machine

Neptune machinery updated quality frequency, quality keep better. Make it easy to start bottle water business.