1600BPH Semiautomatic Bottle Blow Molding Machine is a micro-computer-controlled, semi-automatic hallow four-cavity blowing machine designed for producing plastic hallow containers made of PET. Here are some key specifications and features:

- Production Capacity:

- The machine has a production capacity of 1600 bottles per hour (BPH), making it suitable for small to medium-scale production.

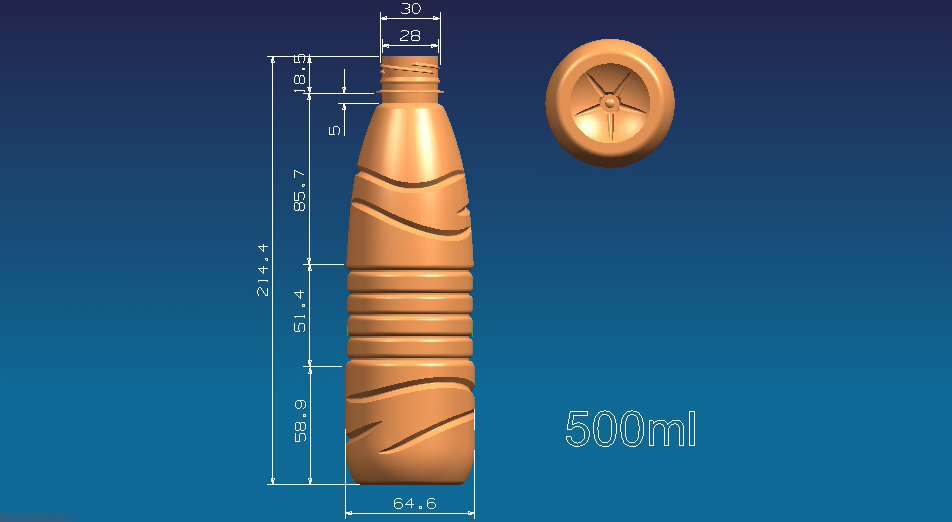

- Bottle Volume:

- Capable of producing plastic hallow containers with a volume range of 0.1L to 2L. This versatility allows for the production of bottles of various sizes.

- Technology:

- Utilizes blow molding technology to shape and form PET plastic into hallow containers.

- Advantages:

- Energy-Saving: Designed with energy-efficient features to optimize power consumption.

- Small Size: Compact design to minimize space requirements.

- Low Investment: Offers a cost-effective solution with a fast return on investment.

- Efficiency: Designed for efficient and reliable operation.

- Reasonable Structure: Incorporates a well-thought-out and structured design.

- Applications:

- Food Industry: Suitable for packaging food products in hallow PET containers.

- Medicine: Used in the pharmaceutical industry for packaging medicines and pharmaceutical products.

- Cosmetic Industry: Ideal for producing hallow containers for cosmetics and personal care products.

- Pesticide-Killer: Applicable to the packaging of pesticide and insecticide products.

- Chemical Industry: Used for packaging various chemical products.

- Beverage Packaging: Suitable for the production of PET bottles for beverages.

- Semiautomatic Operation:

- The term “Semiautomatic” indicates that the machine involves some manual intervention, typically in the loading and unloading of preforms.

- Wide Range of Industries:

- The machine is versatile and finds applications in multiple industries due to its adaptability and efficiency.

The 1600BPH Semiautomatic Bottle Blow Molding Machine offers a balance between production capacity, versatility, and cost-effectiveness, making it a suitable choice for businesses with moderate production needs in various packaging industries.

ROTATING OVEN

Rotary infrared heater heats pre-forms by moving pre-forms to pass through infrared heating area twice. by this method, heating is uniform and of high efficiency,

Rotary infrared heater consists of heating system, cooling system, pre-form conveying system, constant temperature system,etc.

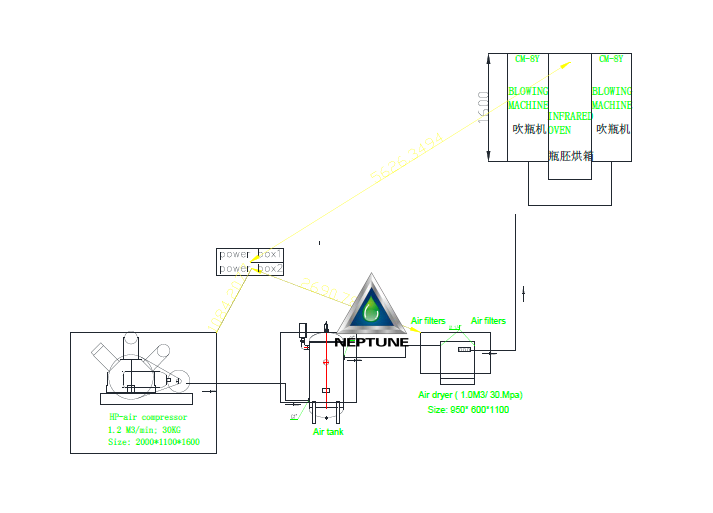

High pressure air compressor(1.2M3/min 30KG); Brand Shangair

Air Dryer with Air Filter

Air dryer is to remove the moisture from the compressed air and lower temperature of the compressed air in the heat exchanger.

Air filter is to clear up the impurities out of the compressed air, like carbon-hydrogen, tiny dust and solid particles .

1th Two cavities blow mold (200-2000ml); 2th Two cavities blow mold (200-2000ml)

Mold-Chiller 3HP Air Type

Air-cooling chiller can fast cooling the blow mold, greatly raise the working efficiency of blow moding machines and obviously improve the bottle quality.

Produce out every plastic bottle 100% clear and perfect.

Water type need connect with an extra water tank by customer self, it is trouble

and easy leak water lead whole factory is water. Air type cooling directly

connection with the mold, Friendly use.

Layout

Stretch Blow Moulding Machine is suitable to produce differently shaped bottles from PET tube. It is widely used to produce Mineral water carbonated drink,

candy sauce, juice, medicine, cosmetic and oil bottle etc.

The machine adopts revolving infrared pre-heater. It ensures extremely even heating for PET preforms.

The machine uses mechanical-double-arm mould clamping which ensure the mould be closed tightly even in high pressure.

The air system has been divided into two parts: Pneumatic action part and bottle blowing part .

It can provide sufficient and steady high pressure for blowing irregularly shaped large bottles.

The machine is also equipped with a silencer and an oiling pump to reduce noise and friction.

The machine can be operated in the step-by-step mode and the semi-auto mode.

The machine is small with low cost, easy and safe to operate. And it meets the need of beverage manufacturer, polyester bottle producer in city and countryside and is ideal bottle blowing equipment for water bottle.

Structure and functions

Main machine: composed of machine body, closing structure, sealing stretching, and blowing machine, all together four parts.

1. Closing structure is composed of fixed mould plate, moving mould plate, cylinder, and double bending arms and connecting poles. The air source is controlled by the helping of the connecting poles and double bending arms; the plates open and close thereby.

2. The sealing stretching is controlled respectively by two left/right cylinders independently, conducting left and right stretching and sealing. It is also controlled by two solenoid valves of two position and five routes. They can adjust the air blowing retention time of the two cylinders respectively.

3. The air source comes from the second level filter first, and then goes to two big size two-position-three-routes solenoid valves to blow high-pressure air to make bottles from perform .

4.The operation screen is installed with microcomputer controller. It has LCD displaying function, manual or automatic functions switches. They control the time of opening and closing of mould, sealing stretching and blowing. Easy and convenient to operate.

Usage and Character

1600BPH SEMI Four cavities Blowing Machine is the new equipment which produces plastic hallow containers of PET. It has the advantages of energy-saving, small size, low investment, (fast money back), efficient, and reasonable structure and is widely used in food, medicine, cosmetic, pesticide-killer, chemical and beverage packaging industries.

Character:

1. Equipped with microcomputer control, easy to operate.

2. Heating part is IR heating tube, controlled by imported controlling silicon. The moving part is equipped with three phases motor, and drived by frequency changing part.

3. There are left and right cylinders in sealing stretching part. the stretching length can be adjusted automatically, and the time for air blowing can be adjusted freely. the bottle blowing can benefit from doing so.

4. The waste air can be exhausted from a silencer inside the machine. It reduces the possibility of creating water drop, and is prevented from making noise.

5. There are two air storage barrels inside the main machine and one high, one low, pressure-reducing valve.